FEATURED PRODUCTS

-

Hartness 835 Stainless Steel Drop Packer0 out of 5

Hartness 835 Stainless Steel Drop Packer0 out of 5 -

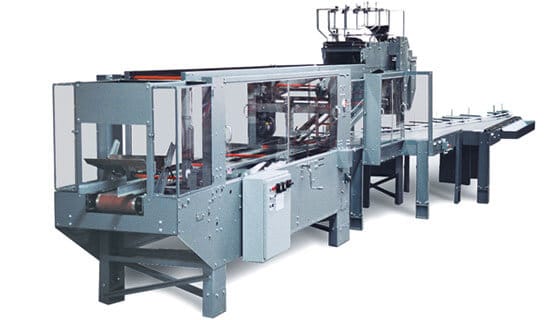

Belcor 250/505 Combo0 out of 5

Belcor 250/505 Combo0 out of 5 -

ADCO 15D105 Cartoner0 out of 5

ADCO 15D105 Cartoner0 out of 5

BEST SELLING PRODUCTS

-

Busse Classic R High Level Bulk Palletizer0 out of 5

Busse Classic R High Level Bulk Palletizer0 out of 5 -

ABC Decasers0 out of 5

ABC Decasers0 out of 5 -

3M Matic Top and Bottom Sealer0 out of 5

3M Matic Top and Bottom Sealer0 out of 5

LATEST PRODUCTS

-

6500 Gallon Stainless Tanks0 out of 5

6500 Gallon Stainless Tanks0 out of 5 -

Flexicon Super Sack Unloading System0 out of 5

Flexicon Super Sack Unloading System0 out of 5 -